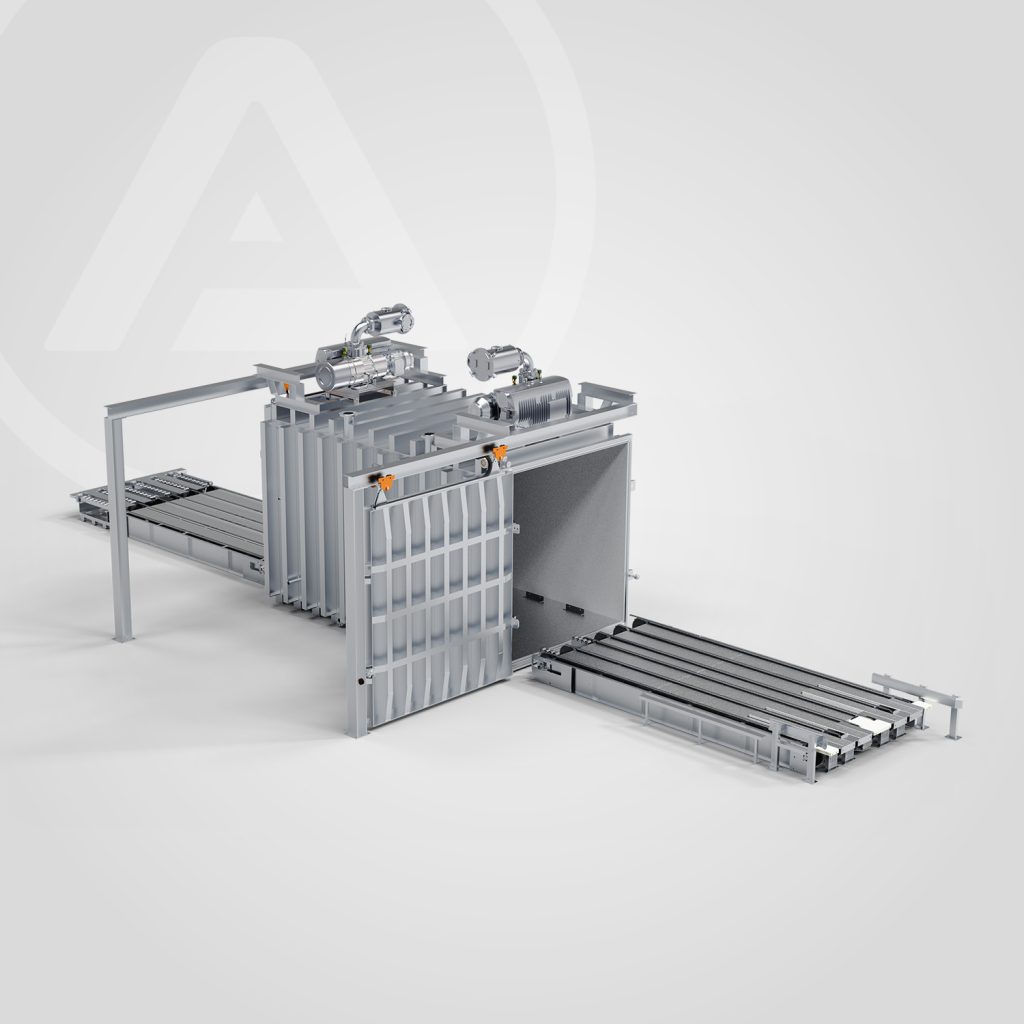

Air handling unit

Description

Air handling unit is designed for climate control and ventilation of growing rooms with a cultivation size from 200 to 1600 m2. Power of the air exchangers and the efficiency of fans are adjusted to the size of growing area and local climate conditions. Using materials and components with increased resistance to harsh conditions dominating inside the mushroom farm, we have managed to achieve a high level of durability and reliability of the offered the products. Optionally, a preheating or cooling system can be installed.

Machinery room

built up inside container or in dedicated room on the farm

Description

Chilled water machinery rooms, which are the source of cooling for mushroom farms, equipped with chilled water aggregates from reputable brands of any design. Pump modules complete with armature and automation that control the operation of all devices are located within the machinery container layered with sandwich panels for insulation. This solution shortens the assembly time of the machinery room at the Customer’s facility. It is possible to locate the machinery room both outside and inside the building.

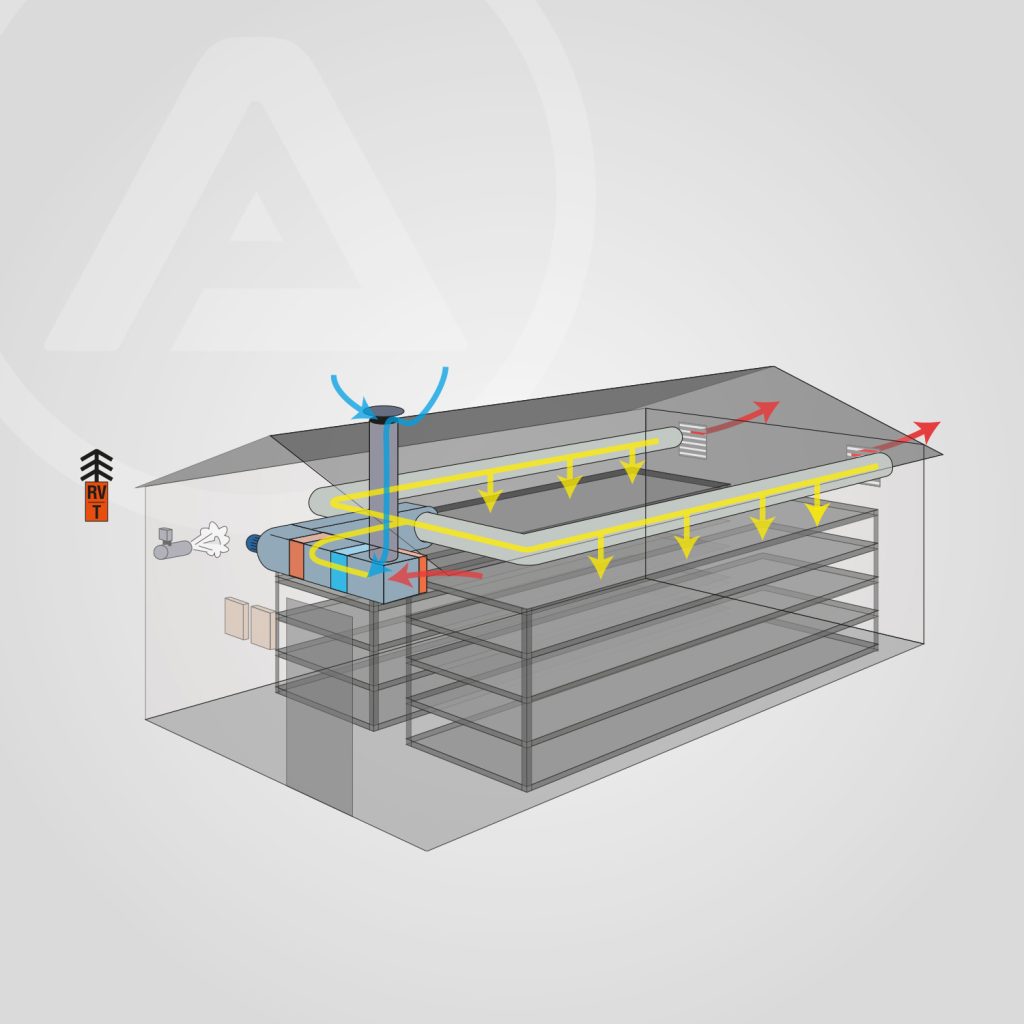

Air distribution system

Description

Elements of a mushroom farm equipment such as overpressure louvers for the gates, ventilation ducts (metal and PVC) and air nozzles are additional accessories to ensure the distribution of air from and to the air conditioning and air handling unit, as well as the removal of air and CO2 from the growing room.

The air distribution system consists of:

- Fresh air intake ducts

- Air supply and recirculation ducts

- Air distribution film ducts with PCV nozzles

- Overpressure louvers, placed into external gates leafs

- Ceiling exhaust ducts equipped with exhaust fans (alternative option to overpressure louvers)

Air distribution nozzles

Description

Air distribution nozzles installed in the air ducts are an extremely important element of the mushroom farm equipment, they evenly distribute air flow inside the growing rooms. The air nozzle is made of two parts, which allows for easy installation in existing air ducts. Air stream coming out of the AHU is turbulent inside the PVC air ducts but it is easily controlled with the air distribution nozzles. Also, the role of this product is to properly direct the air stream so that it reaches the lowest growing shelf.

Shocker with air-coolers

for mushroom farms

Description

Shockers are made to rapidly cool mushroom immediately after picking. These rooms are the first stage in the mushroom cooling cycle. Preservation of mushrooms is essential for sustainable maintenance of quality and freshness. The size and performance of shockers is designed to individual needs of the Client.

Vacuum shocker

for mushroom farms

Description

Shocker cooling rooms are responsible for rapid mushroom cooling immediately after picking. The cooling is done using vacuum technology. Under vacuum conditions, water vapor is evaporated from the mushroom, which facilitates its cooling through dedicated refrigeration equipment. The automation system controls parameters like the degree of vacuum and the temperature of the goods. At the customer’s request, it is possible to make a system for automatic loading of goods into the room.

Cold storage

Description

Cooling, sorting or packing rooms constitute the next stage of the cooling cycle. Comprehensive solutions are provided for the storage and distribution of fresh mushrooms. The equipment is always designed to the specific rooms and the purpose that they serve.

Mobile cooler

Description

This cooling unit is used directly in the growing room as a device to support the operation of the air handling unit in extreme situations, such as in the case of very active compost after filling into the growing room. The unit has a built-in compressor cooling system, making it an independent source of cooling. The unit must be supplied with electrical power and tap water. Fans built into the unit provide circulation of cooled air in the growing room.

Climate control system

Description

As an official distributor of Fancom our company supplies and performs installation work of this advanced computer system for controlling the microclimate inside the growing rooms, dedicated for the mushroom growing industry. This system monitors the level of humidity, temperature and CO2 concentration, as well as the main parameters of the air inlet to the AHU (Air Handling Units). After taking measurements to ensure the right microclimate conditions for a given growing phase, it controls external cooling, heating and humidification systems.

*On a special request our company can supply alternative control systems.

Air humidification systems

Description

A high-pressure water humidification system of air in the growing rooms is used to maintain the appropriate level of relative humidity, which has a significant impact on the microclimate in the closed room. It causes an increase in crop yields and improves their quality. The system operates at a pressure of 70 bar, ensuring that the water droplets are crushed to a size of less than 15 µ, which then evaporate by taking away the heat contained in the air. An inverter is used to regulate the pump, whose task is to control the pressure at the inlet, thus protecting the pump from dry running, as well as the pressure on the system.

A steam air humidification system, like a water humidification system, is used to maintain an appropriate level of relative humidity, which has a significant impact on the microclimate in the rooms. Steam humidification involves the injection of small amounts of steam into the supply duct which means steam mixed with air is distributed throughout the

entire chamber. Control of the amount of steam fed is carried out by means of control valves installed at the steam pipeline outlets. The degree of opening is determined by the signals that are sent by the controllers of the climate control system.