Gates for compost plants

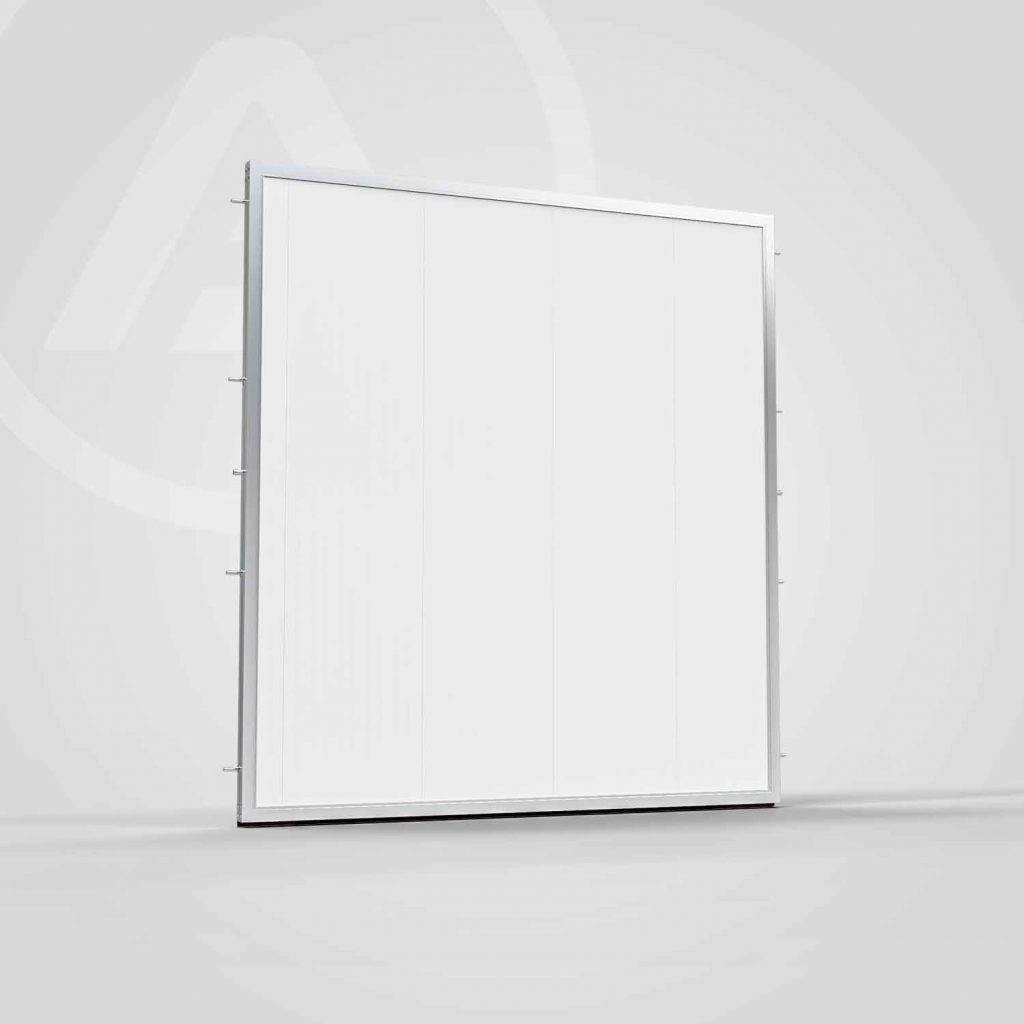

Description

The purpose of the gate is to provide easy access to the bunker on the composting plant with closed Phase I while maintaining maximum tightness and thermal insulation. The seal is ensured with the use of a high-end silicone gasket and specially designed supports that can be adjusted in three positions. Gate leaf is made of PIR core sandwich panels with stainless steel cladding, enveloped in a frame made of stainless steel shaped profiles. Due to the large size, the structure of the gate is reinforced with stainless steel profiles, which provide structural integrity of the gate.

Gates for compost plants

Description

The gate is designed to provide easy access to the tunnel while maintaining maximum seal and thermal insulation of the tunnel. The tight seal is accomplished with the use of a high-end silicone gasket and specially designed brackets with the possibility of adjustment in three positions. The gate leaf is made of PIR sandwich panels, stainless steel and HPS cladding, enveloped in a frame made of aluminum profiles. The tunnel gate can also be equipped with an inspection window 800 mm x 800 mm. Tunnel gate can be designed in two options: sliding or tilting.

Gate opening mechanism

Description

The hydraulic opening mechanism is used to lift and slide the gates for Phase 1 bunkers. The mechanism can be made entirely of hot-dip galvanized steel or stainless steel. Raising the gate can be accomplished with the use of a manual pump and hydraulic cylinders, and optionally with a hydraulic pump controlled by wireless electric system. The electrical pump is provided with a rechargeable battery.

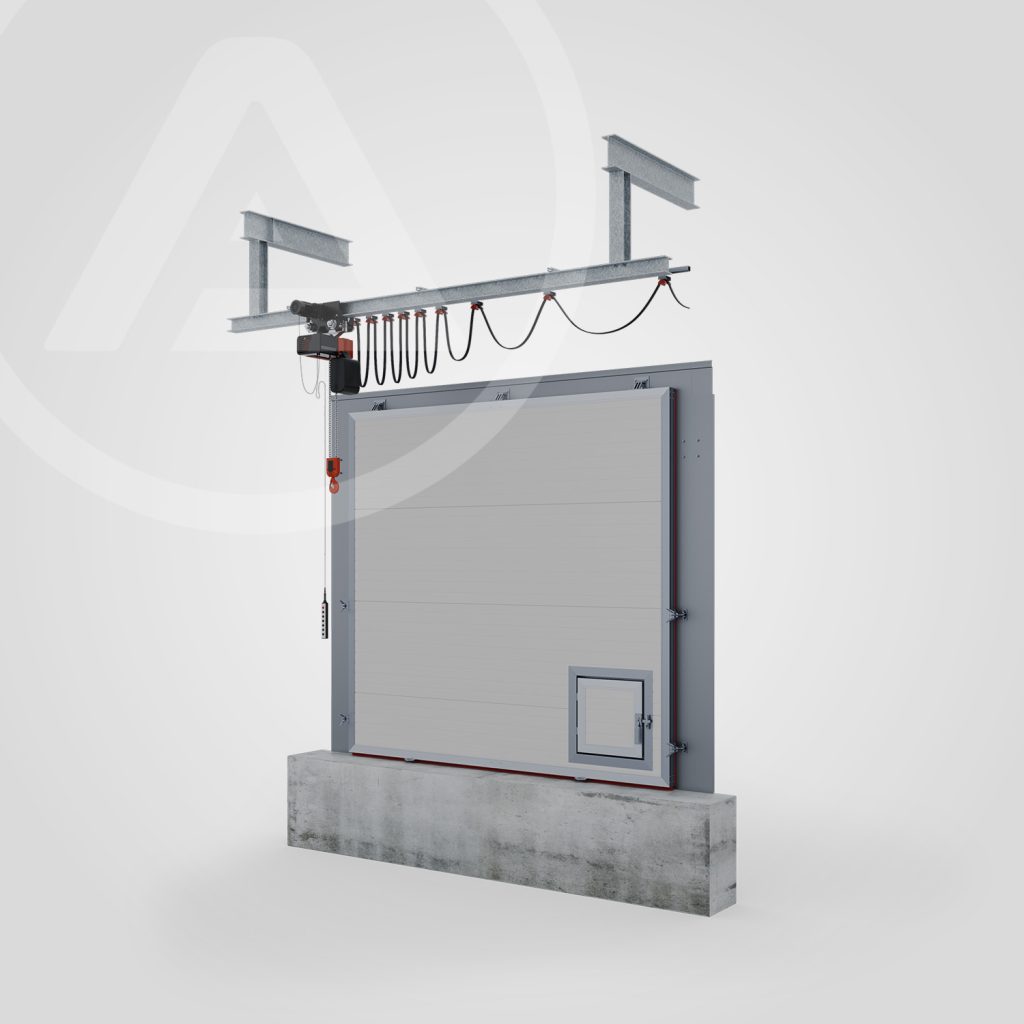

Gate opening mechanism on an electric winch

Tunnels Phase II and III

Description

The opening mechanism on electric winches is used to lift the gates of Phase II and III tunnels suspended on hinges at their top. Lifting of the gates is performed by electric winches that move along a track mounted above the gates. Next to the rail track there is suspended busbar supplying the electric winches. Each winch can be equipped with a wired or wireless remote control. The number of winches required for each side of the Phase II and III halls is selected according to the number of tunnels and the length of the corridors in front of the tunnels. Additionally each gate is equipped with safety mechanism which protects the gate against unintentional closure.

Gate opening mechanism on hydraulic cylinders

Tunnels Phase II and III

Description

The opening mechanism on hydraulic cylinders is used to lift the gates of Phase II and III tunnels suspended on hinges in their upper part. Lifting of the gates is performed by hydraulic cylinders which are part of the hydraulic system. The system consists of a pump, an oil tank, a system with valves, a control system and just the hydraulic cylinders. The control of opening and closing can be based on the use of a stationary or portable remote control, as well as physical buttons placed directly at each gate.