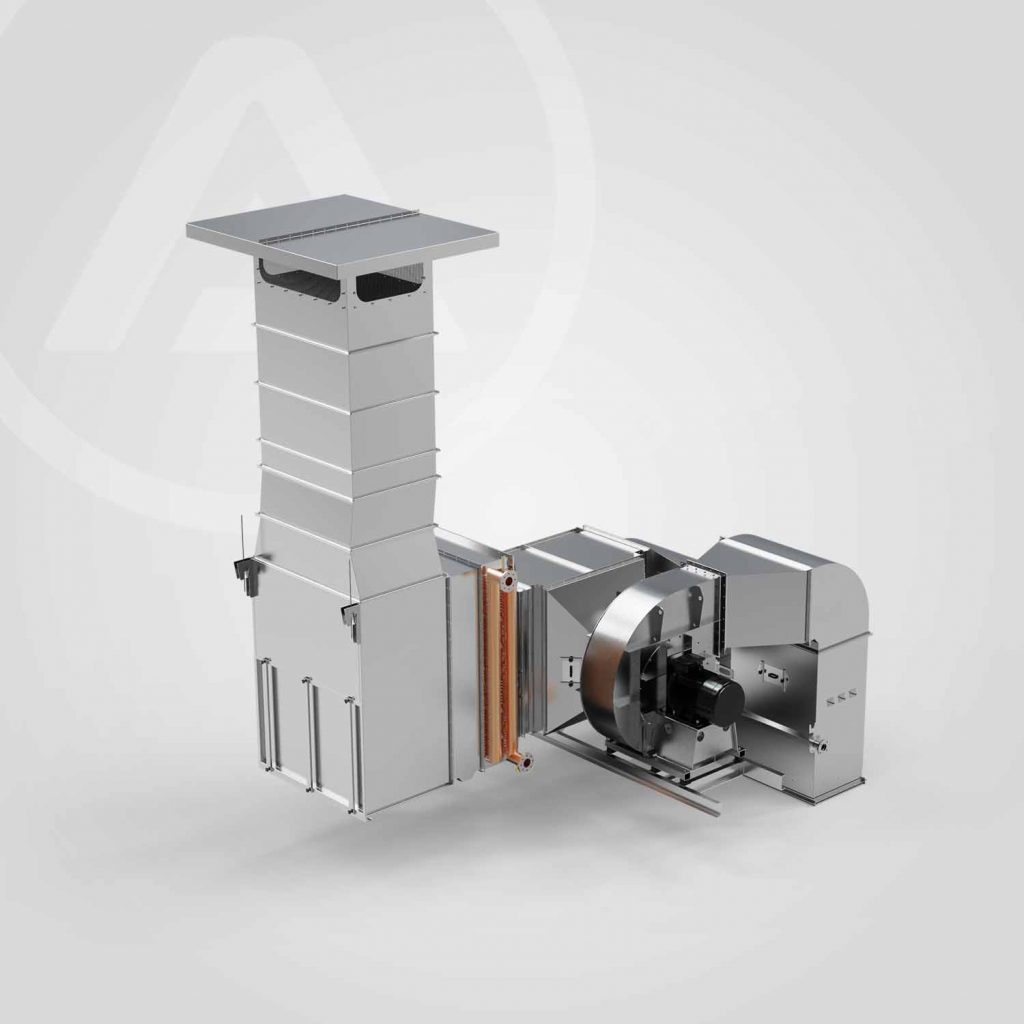

Air handling units

Description

This air handling unit is designed for air conditioning/ventilation of tunnels with a capacity of up to 400 tons. The design of the AHU is adjusted depending on the way that the tunnels are made. Both the power of the exchangers as well as the fan performance is adjusted to the given tunnel capacity. Using only high quality materials in the manufacturing processes, high level of durability and reliability of the offered products was achieved.

Floor aeration system

Description

Complete air supply system for Phase I bunkers. The system consists of a radial high-pressure fan and an air distribution manifold with connections to the aerated floor. It is a possible to design many different configurations of materials and equipment.

Aerated floor

Description

The aerated floor consist of pipes system poured into the concrete floor, which evenly distributes air trough the whole floor, air nozzles (spigots) and protectors. Nozzles’ job is to narrow and direct the air flow in order to properly aerate the compost. The nozzle is made of HDPE polypropylene. In order to achieve proper seal it is recommended to use additional sealant. Aerated floor can be executed with air recirculation system.

Air nozzles for aerated floor

Description

The nozzles for the aerated floor are installed in pipes located in the bunker floor. Their job is to narrow and direct the air flow in order to properly aerate the compost. The nozzle is made of HDPE polypropylene. In order to achieve proper seal it is recommended to use additional sealant.

Sensor’s mechanism for temperature and oxygen

Description

The temperature or oxygen sensor socket is mounted on the roof over the bunkers. It is used for placing a lance with a compost temperature or an oxygen sensor inside. The socket has a movable mechanism that allows easy insertion of a long lance with a sensor at the end into a compost to take readings.

Lance to climate control system

Description

The lance is made of a round stainless pipe with a handle on one side and a gland to mount the temperature sensor or air sampling holes on the other side. The temperature sensor lance is used to take compost temperature readings. The oxygen lance, on the other hand, is inserted into the compost to take oxygen level readings.

Machinery room

Description

The chilled water machine room is the source of cooling for the installation serving the Phase III tunnels. Depending on the customer’s needs, it is possible to individually select the size, number and type of chilled water units, which are the source of cooling in the machine room. The set of equipment of the chilled water machinery room additionally consists of pump modules, a set of valves and fittings and automatics that control the operation of the equipment. There is a possibility of implementing dedicated software for remote access, signaling the status of equipment operation, including alarms and creating databases for electricity consumption by the equipment. The equipment can be located in a container construction made of sandwich panels or integrated into a building in a space provided by the Investor.

Chemical fogging system

Description

It is extremely important during the compost production to maintain hygiene and disinfection of spawning and emptying halls as as well as Phase II and III tunnels, mycelium coldstore, and other working areas of the Phase II and III building. One of the most important factors affecting good hygiene is disinfection, for executing of which we developed an automatic chemical fogging system based on dosing chemicals and creating chemical mist in working halls using a system of nozzles connected to a hydraulic installation and control system. Chemical fog, filling the entire volume of the room, allows chemical compounds to effectively fight bacteria, molds and diseases contained in the air and on the surfaces of walls, floors and ceilings of working rooms.

Humidification system

Description

The use of the humidification system completely eliminates the „overdry” effect in the lower parts of the compost in the tunnel in the phase of mycelium spawn-run and significantly reduces the loss of weight, which in turn affects the quantity and quality of the compost. The humidification system consists in humidifying the air that is blown under the grids in the Phase III tunnel. The working pressure of the pumps is 60 bar, this pressure allows to create the water mist and properly build-in it into the compost. The maximum amount of water supplied from three sections of high-pressure nozzles to one tunnel is up to 120 litres/h. The system allows for automatic or manual control of every section of nozzles for each tunnel, thus regulating the amount of served moisture depending on the moisture content in the compost and the actual production phase. The whole installation is made of stainless steel.

Laboratory equipment

Description

For performing laboratory tests and determining the most important compost parameters such as nitrogen level, moisture, organic matter content, ash, Ph, etc., we offer a full set of laboratory equipment and tools, such as high quality Kjeldahl system distillers, titrators, digestors, sample systems, scrubbers and other devices such as moisture analyzers, muffle furnaces, incubators, autoclaves, laboratory refrigerators, etc. We also cooperate with companies that have the largest databases for near-infrared spectroscopy (NIR) compost analysis systems and can provide and implement the most advanced equipment for conducting laboratory tests according to the NIR method.

Climate control system

Description

As an official distributor of Fancom our company supplies and performs installation work of this advanced computer system for controlling the main parameters of Phase I fermentation bunkers. In the Phase 1 Bunkers the system monitors the aeration level and temperature and then adjust the air supply fans to keep proper aeration and temperature in the compost.

Climate control system

Description

As an official distributor of Fancom our company supplies and performs installation work of this advanced computer system for controlling the main parameters of Phase II/III tunnels. In the pasteurization and spawn-run tunnels the system controls level of humidity, temperature and O2 concentration, as well as the main parameters of the air inlet and outlet to/from the AHU (Air Handling Units) and recirculation. After taking measurements to ensure the right microclimate conditions for a given phase, it controls external aeration, cooling and humidification systems.